INTRODUCTION TO AIR CONDITIONING

INTRODUCTION TO AIR CONDITIONING

A few points about the air conditioning timeline 1842 Lord Kelvin lays down air conditioning principles 1902 Willis Haviland Carrier begins the manufacture of air conditioning and creates the basis of this technology 1928 Discovery of the refrigerant freon by Thomas Midgley Jr. 1957 The first rotary compressors are manufactured 1958 Panasonic introduces its first domestic air conditioner. 1977 Heat pumps begin to be used.

The air conditioning

It is a technological system by means of which we heat or cool air to have an area or volume of air with certain thermal and humidity conditions. The principle on which it is based is that of a refrigeration system. When we put two bodies of different temperatures in contact, the one with a higher temperature gives up thermal energy to the one with a lower temperature until the temperature of both is equal. The direction in which the heat moves is from the point of higher temperature to the point of lower temperature, therefore, if we want to move in the opposite direction, that is, from the point of lower temperature to the point of higher temperature, we will have to give it some energy, to we will use a motor for this.

THE OUTDOOR UNIT

The outdoor unit in an air conditioner is the part made up of the condenser, the compressor, the fan, and the expansion valve.

THE CONDENSER: it is the part in charge of removing the heat from the coolant, which will be transferred to a fluid or air (direct expansion). The refrigerant goes from a gaseous state to a liquid, therefore there is a heat exchange. Therefore, we have two sections, one is the cooling of the refrigerant gas and the second is the condensation of the gas, transforming it into liquid.

The COMPRESSOR: Here the gas that comes from the evaporator is compressed, it comes in a gaseous state. When compressing it, we increase the pressure and from here it will go to the condenser.

REVERSIBLE VALVE: This valve performs the cycle change in the air conditioning, from cold to hot or from hot to cold.

EXPANSION VALVE: This valve regulates the flow of refrigerant according to the pressure required. The refrigerant will be cooled due to this pressure by means of the evaporator.

FAN: This part is responsible for ventilating the outdoor unit, extracting heat in summer and cold in winter, from this unit.

THE INDOOR UNIT

In the indoor unit there is a heat exchange, the hot air gives up its thermal energy to the refrigerant, heating the refrigerant and cooling the air, then a fan distributes this air through the area to be cooled. This unit has thermal sensors that go to the thermostat. It is built by an outdoor unit (E.U) and several indoor units. (U.I) It is noted with the following form, AxB, where A is the No. of indoor units and B is the outdoor unit. Example: 1x1, 2x1, 3x1,… .6x1, etc. For indoor and outdoor units you are interested in: - the heating capacity (kW) - the cooling capacity (kW) - electricity consumption - the SEER (seasonal energy coefficient) cold - the SCOP (seasonal energy coefficient) heat - the EER , “Nominal energy coefficient, cold - sound level (dB) - air flow (m3 / h) - -cooling distances

EVAPORATOR: This device will be in charge of making a change of state, from liquid to gaseous. This change of state occurs in the refrigerant fluid.

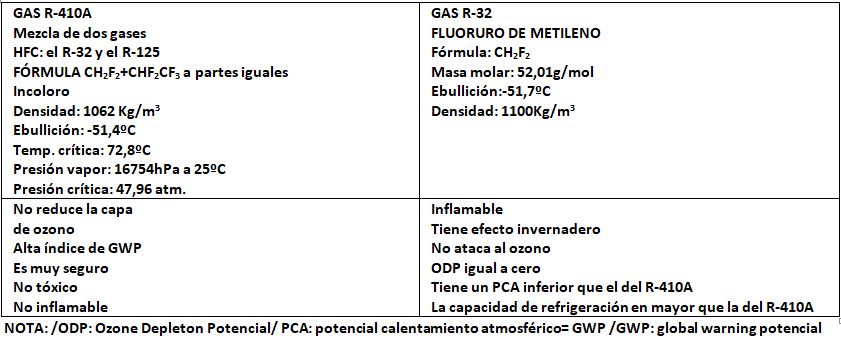

(FLUIDS) REFRIGERANTS (R-32 AND R410A): For an air conditioner to do its job, it uses gases. These gases serve to lower the temperature, or maintain it in a certain area, for this it undergoes a series of transformations that constitute a cycle, it is the refrigeration cycle. These gases must comply with a regulation whose purpose is to make them efficient, but protecting nature. In this protection of nature we will look at the conservation of the ozone layer and the warming of the atmosphere. For the protection of the ozone layer, the use of gases with pure HCFC is prohibited and for atmospheric warming we will be careful with the GWP (global warming potential). There are a large number of refrigerant gases, depending on the use or application, but the most used are R410A and R-32. NOTE: HCFC: hydrochlorofluorocarbon

REFRIGERATION LINES: The set of tubes in charge of transporting the refrigerant is called the refrigeration line. To install the refrigeration line we have to take into account the refrigeration distances, both vertical and horizontal, these have maximum values, given by the manufacturer. Sometimes we can exceed these distances by a few percentages, also determined by the manufacturer. This is done by increasing the refrigerant charge per linear meter of pipe.